|

1. |

EXECUTIVE SUMMARY AND CONCLUSIONS |

|

1.1. |

Summary |

|

1.2. |

Definitions |

|

1.3. |

Description and analysis of the main technology components of printed, flexible and organic electronics |

|

1.4. |

Market potential and profitability |

|

1.5. |

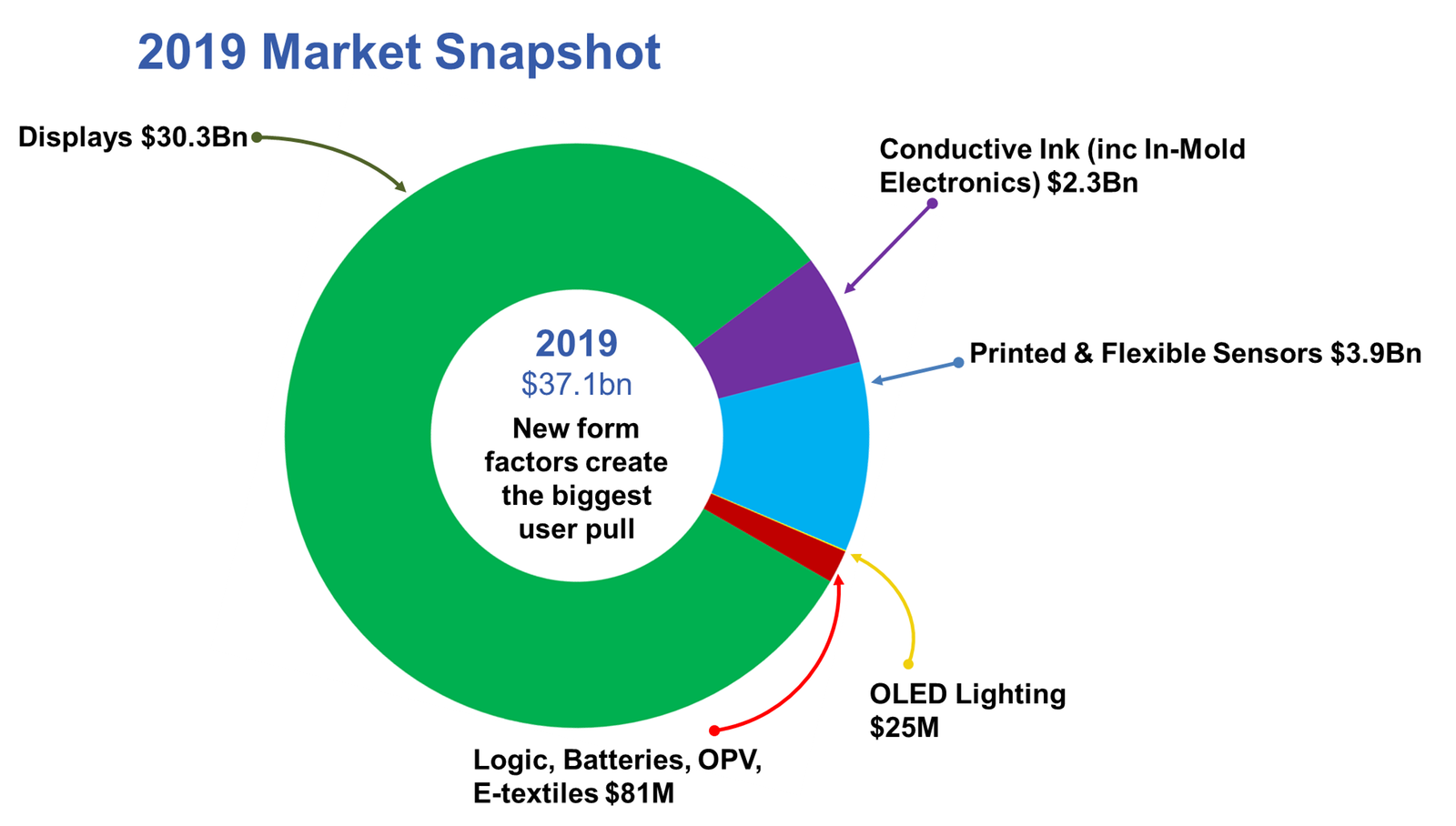

Current market size |

|

1.6. |

Total Market Size by Component 2020-2030 |

|

1.7. |

Printed versus non-printed electronics |

|

1.8. |

Market Size for Printed Electronics Components and Materials 2020-2030 |

|

1.9. |

Total market value of printed versus non-printed electronics 2020-2030 |

|

1.10. |

Findings on printed versus non-printed electronics |

|

1.11. |

Flexible/conformal versus rigid electronics |

|

1.12. |

Key components needed for flexible AMOLED displays |

|

1.13. |

Market size of Flexible/ Conformation Electronics 2020-2030 |

|

1.14. |

Market value of flexible/conformal versus rigid electronics chart and table |

|

1.15. |

Market by territory |

|

1.16. |

The value chain and unmet needs |

|

1.17. |

The Value Chain: Printed, Flexible & Organic Electronics |

|

1.18. |

The value chain is unbalanced |

|

1.19. |

But many have shifted to provide complete solutions because they are Pioneering New Market Creation |

|

1.20. |

Go to Market Strategies |

|

1.21. |

Strategy 2: Replace or do something simple in existing electronics/electrics |

|

1.22. |

Strategy 3: Creating New Markets |

|

1.23. |

What end users want - results from end user surveys |

|

1.24. |

More companies are moving downstream to offer complete products |

|

1.25. |

Hybrid Electronics |

|

2. |

MARKET DRIVERS, LESSONS AND STRATEGIES FOR PRINTED ELECTRONICS |

|

2.1. |

What is Printed, Flexible, Organic Electronics? |

|

2.2. |

Printed, organic and flexible electronics value |

|

2.3. |

Features that are associated with Printed Electronics |

|

2.4. |

Giant industries collaborate for the first time |

|

2.5. |

Recent Investments |

|

2.6. |

Printed electronics in the retail industry |

|

2.7. |

Printed electronics in healthcare |

|

2.8. |

Printed electronics in wearable technology |

|

2.9. |

Printed electronics in vehicles |

|

2.10. |

Printed electronics in consumer electronics, IoT, etc. |

|

2.11. |

Creating successful new products leveraging the benefits of printed electronics is challenging |

|

2.12. |

Cost reduction has been more commercially successful... |

|

2.13. |

...but if it is the only differentiator it can struggle |

|

2.14. |

Competing on more than cost has been the most successful |

|

3. |

CONDUCTIVE INKS |

|

3.1. |

Conductive Ink Options |

|

3.2. |

Conductive inks and pastes |

|

3.3. |

Characteristics of Ag nano inks |

|

3.4. |

Flake versus nanoparticle inks |

|

3.5. |

Explanation of conductive ink forecasts |

|

3.6. |

Conductive Inks/Pastes, Polymer Thick Film (PTF): Key Suppliers |

|

3.7. |

Nano particle conductive Inks/Pastes: Key Suppliers |

|

3.8. |

Conductive Ink 2019 Market by Application $ millions |

|

3.9. |

Conductive inks forecasts 2020-2030 $ millions |

|

3.10. |

Conductive Ink in Photovoltaics |

|

3.11. |

Silver consumption per PV wafer greatly improves |

|

3.12. |

Touch screen market |

|

3.13. |

Touch screen edge electrodes: getting finer |

|

3.14. |

Automotive industry: Increasing use cases |

|

3.15. |

Simple Circuit Printing |

|

3.16. |

Structural Electronics |

|

3.17. |

3D antennas |

|

3.18. |

In-Mold Electronics (IME) |

|

3.19. |

In-Mold Electronics (IME) Process and Examples |

|

3.20. |

In-Mold Electronic Process |

|

3.21. |

Comments on IME requirements |

|

3.22. |

New ink requirements: stretchability |

|

3.23. |

New ink requirements: portfolio approach |

|

3.24. |

General application areas for IME |

|

3.25. |

In-Mold Electronics (IME) Case Studies |

|

3.26. |

Automotive: direct heating of headlamp plastic covers |

|

3.27. |

3D printed electronics |

|

3.28. |

Why 3D Printed Electronics? |

|

3.29. |

Stretchable inks for E-Textiles |

|

3.30. |

Conformal EMI shielding |

|

3.31. |

Other Conductive Ink Applications |

|

3.32. |

Conductive Ink Summary |

|

3.33. |

Company profiles related to this chapter |

|

4. |

DISPLAYS |

|

4.1. |

Display drivers |

|

4.1.1. |

Market drivers |

|

4.1.2. |

New and established display technologies compared |

|

4.2. |

OLED Displays |

|

4.2.1. |

OLED displays |

|

4.2.2. |

Why choose OLED over LCD? |

|

4.2.3. |

Drivers for Display Innovation: OLED Displays |

|

4.2.4. |

Evolution of the OLED industry |

|

4.2.5. |

Examples of OLED products |

|

4.2.6. |

Global OLED Production Capacity |

|

4.2.7. |

OLED Display Market 2017-2018 by Value and SQ Meters |

|

4.2.8. |

OLED market forecasts 2020-2030 $ Millions |

|

4.2.9. |

OLED Display Forecasts 2019-2029 Area (sqm) by Form Factor (Rigid versus Flexible) |

|

4.2.10. |

OLED Display Forecasts 2019-2029 Area (sqm) by Form Factor (Rigid versus Flexible) |

|

4.2.11. |

OLED Display Forecasts 2019-2029, Panel Numbers by Form Factor (Rigid versus Flexible) |

|

4.2.12. |

First step towards flexible: OLED on plastic substrate |

|

4.2.13. |

The rise of plastic and flexible AMOLED |

|

4.2.14. |

Case study: the Apple Watch |

|

4.2.15. |

Case study: Motorola shatterproof screen |

|

4.2.16. |

Key components needed for flexible AMOLED displays |

|

4.2.17. |

Roadmap towards flexible AMOLED displays and flexible electronics devices |

|

4.2.18. |

When will foldable displays take off? |

|

4.2.19. |

Flexible OLEDs: First Foldable Display Comes to Market |

|

4.2.20. |

Printing OLEDs |

|

4.2.21. |

Inkjet Printing Organic Materials for Thin Film Encapsulation of OLEDs |

|

4.2.22. |

Printed OLEDs: Printing RGB materials |

|

4.2.23. |

Inkjet printing: is it worth it? |

|

4.2.24. |

R G B inkjet printing in displays |

|

4.2.25. |

Printed OLED Displays: Key Players |

|

4.2.26. |

Printed OLEDs are finally commercial |

|

4.2.27. |

Printed OLED TVs |

|

4.2.28. |

JOLED: First Commercial Printed OLED Display |

|

4.2.29. |

JOLED Printed OLED Strategy |

|

4.2.30. |

UDC: Organic vapour jet printing |

|

4.2.31. |

Fraunhofer IAP'S ESJET printing |

|

4.2.32. |

Printing in Quantum Dot OLED Hybrid Displays |

|

4.3. |

Electrophoretic and other bi-stable displays |

|

4.3.1. |

Electrophoretic and other bi-stable displays |

|

4.3.2. |

Electrophoretic e-readers decline - what's next? |

|

4.3.3. |

The Holy Grail: Color E-paper Displays |

|

4.3.4. |

New color display from E Ink without filters |

|

4.3.5. |

Signage |

|

4.3.6. |

Colour Electrophoretic Displays are Available $500 million market for e-paper in 2017 |

|

4.3.7. |

E-Paper Revenues |

|

4.3.8. |

The early years of flexible E-ink displays |

|

4.3.9. |

Other players in Reflective BiStable Displays |

|

4.3.10. |

Electrowetting displays |

|

4.3.11. |

Electrowetting displays: Liquavista |

|

4.3.12. |

Electrowetting displays: Etulipa |

|

4.3.13. |

Electrophoretic and Bi-Stable displays Market Forecasts 2020-2030 $ millions |

|

4.4. |

Electrochromic displays |

|

4.4.1. |

Electrochromic displays |

|

4.4.2. |

Ynvisible Electrochromic Displays |

|

4.4.3. |

Electrochromic displays market forecasts 2020-2030 |

|

4.5. |

AC Electroluminescent displays |

|

4.5.1. |

EL technology |

|

4.5.2. |

AC Electroluminescent (EL) Displays |

|

4.5.3. |

Electroluminescent displays market forecasts 2018-2029 $ millions |

|

4.6. |

Thermochromic displays |

|

4.7. |

Flexible LCDs |

|

4.7.1. |

Flexible LCDs |

|

4.7.2. |

Flexible LCDs from FlexEnable |

|

4.7.3. |

Flexible LCDs: Conclusions |

|

4.7.4. |

Company profiles related to this chapter |

|

5. |

LED AND OLED LIGHTING |

|

5.1. |

OLED Lighting |

|

5.1.1. |

Value proposition of OLED vs LED lighting |

|

5.1.2. |

OLED lighting: solid-state, efficient, cold, surface emission, flexible......? |

|

5.1.3. |

OLED Lighting Status |

|

5.1.4. |

Cost challenge set by the incumbent (inorganic LED) |

|

5.1.5. |

Comparing OLED and LED lighting |

|

5.1.6. |

OLED Lighting is more challenging than OLED displays in terms of lifetime and light intensity requirements |

|

5.1.7. |

OLED lighting - cost projection |

|

5.1.8. |

Market announcements |

|

5.1.9. |

Technology progress |

|

5.1.10. |

OLED Lighting - market penetration |

|

5.1.11. |

OLED lighting value chain |

|

5.1.12. |

S2S Lines: OLEDWorks in Aachen (ex-Philips line) |

|

5.1.13. |

S2S lines: LG display: Gen-2 and Gen 5 |

|

5.1.14. |

R2R line: Konica Minolta |

|

5.1.15. |

But why is it so difficult to reduce cost?? |

|

5.1.16. |

OLED Lighting Market Forecast |

|

5.1.17. |

OLED Lighting Market Forecast 2020-2030 $ millions |

|

5.2. |

Printed LED lighting |

|

5.2.1. |

Printed LED lighting |

|

5.2.2. |

Nth Degree - Printed LEDs |

|

6. |

PHOTOVOLTAICS |

|

6.1. |

Introduction to photovoltaic technologies |

|

6.2. |

Comparison of photovoltaic technologies |

|

6.3. |

Efficiencies of Different Solar Technologies: Cells and Modules |

|

6.4. |

Printing in crystalline silicon PV |

|

6.5. |

Thin film photovoltaics |

|

6.6. |

Value propositions—beyond conventional silicon |

|

6.7. |

Amorphous silicon |

|

6.8. |

CdTe and CIGS |

|

6.9. |

DSSCs |

|

6.10. |

Organic PV (OPV) |

|

6.11. |

OPV: Typical device architectures |

|

6.12. |

R2R solution vs R2R evaporation |

|

6.13. |

OPV Progress |

|

6.14. |

Solution Processed 17.5% tandem OPV (Aug 2018) |

|

6.15. |

Examples of Organic PV |

|

6.16. |

OPV installations |

|

6.17. |

Challenges Commercializing Organic PV |

|

6.18. |

Konarka vs Heliatek: a case study |

|

6.19. |

Case study: Konarka's failure |

|

6.20. |

Heliatek: R2R evaporated OPV |

|

6.21. |

Latest progress update |

|

6.22. |

Perovskites |

|

6.23. |

Research-cell efficiencies of different solar technologies |

|

6.24. |

Perovskite structure |

|

6.25. |

Working principle |

|

6.26. |

Evolution of Perovskite Development |

|

6.27. |

Structures/architectures of perovskite solar cells |

|

6.28. |

Perovskite solar cell evolution |

|

6.29. |

Perovskite PV Commercial Opportunity |

|

6.30. |

Perovskite PV Applications and Challenges |

|

6.31. |

The Achilles' Heel |

|

6.32. |

Efforts to overcome challenges |

|

6.33. |

Efforts to overcome challenges |

|

6.34. |

Overview |

|

6.35. |

Pilot-scale capacity |

|

6.36. |

Large scale roll-to-roll printed perovskite solar cells |

|

6.37. |

Microquanta Semiconductor |

|

6.38. |

Unique features are required where silicon PVs cannot provide |

|

6.39. |

Application roadmap of perovskite photovoltaics |

|

6.40. |

Market trends and forecasts |

|

6.41. |

Company profiles related to this chapter |

|

6.42. |

Perovskite Photovoltaics 2018-2028 |

|

7. |

PRINTED, FLEXIBLE BATTERIES |

|

7.1. |

Introduction to batteries |

|

7.2. |

ページTOPに戻る

- Global Shared Mobility Market Size Study & Forecast, by Service Model (Ride-Hailing, Bike Sharing, Ride Sharing, Car Sharing), by Channel (Online, Offline) and Regional Forecasts 2025-2035

- Global Drive-in Movie Theater Market Size study & Forecast, by Type (Classic Drive-Ins, Pop-Up Drive-Ins, Multiplex Drive-Ins) by Screen Size (Small, Medium, Large) and Regional Forecasts 2025-2035

- Global Contract Logistics Market Size Study & Forecast, by Service (Transportation, Warehousing, Distribution), by Type (Outsourcing, Insourcing) and Regional Forecasts 2025-2035

- Global Airline Ancillary Services Market Size study & Forecast, by Type (Baggage Fees, Onboard Retail & A-La-Cart, Airline Retail, Airline Retail & FFP Miles Sale, Others) by Carrier Type (Full-Service Carrier, Low-Cost Carrier) and Regional Forecasts 2025-2035

- 2026-2031年 グローバル電磁シミュレーションソフトウェア市場規模・シェア・動向分析レポート:企業別、タイプ別、用途別、地域別

- 2026-2031年 世界中古商品取引プラットフォーム市場規模・シェア・動向分析レポート:企業別、種類別、用途別、地域別

- 2026-2031年 グローバル衛星レーザー通信システム市場規模・シェア・動向分析レポート:主要企業別、タイプ別、用途別、地域別

- 2026-2031年 グローバル5Gアプリケーションおよびサービス展望 市場規模、シェア、トレンド分析レポート:企業別、タイプ別、アプリケーション別、地域別

- 2026-2031年 世界有人警備(有人警護)市場規模・シェア・動向分析レポート:企業別、タイプ別、用途別、地域別

- 2026-2031年 世界冷却型インガスカメラ市場規模・シェア・動向分析レポート:企業別、タイプ別、用途別、地域別

本レポートと同じKEY WORD()の最新刊レポート

- 本レポートと同じKEY WORDの最新刊レポートはありません。

よくあるご質問

IDTechEx社はどのような調査会社ですか?

IDTechExはセンサ技術や3D印刷、電気自動車などの先端技術・材料市場を対象に広範かつ詳細な調査を行っています。データリソースはIDTechExの調査レポートおよび委託調査(個別調査)を取り扱う日... もっと見る

調査レポートの納品までの日数はどの程度ですか?

在庫のあるものは速納となりますが、平均的には 3-4日と見て下さい。

但し、一部の調査レポートでは、発注を受けた段階で内容更新をして納品をする場合もあります。

発注をする前のお問合せをお願いします。

注文の手続きはどのようになっていますか?

1)お客様からの御問い合わせをいただきます。

2)見積書やサンプルの提示をいたします。

3)お客様指定、もしくは弊社の発注書をメール添付にて発送してください。

4)データリソース社からレポート発行元の調査会社へ納品手配します。

5) 調査会社からお客様へ納品されます。最近は、pdfにてのメール納品が大半です。

お支払方法の方法はどのようになっていますか?

納品と同時にデータリソース社よりお客様へ請求書(必要に応じて納品書も)を発送いたします。

お客様よりデータリソース社へ(通常は円払い)の御振り込みをお願いします。

請求書は、納品日の日付で発行しますので、翌月最終営業日までの当社指定口座への振込みをお願いします。振込み手数料は御社負担にてお願いします。

お客様の御支払い条件が60日以上の場合は御相談ください。

尚、初めてのお取引先や個人の場合、前払いをお願いすることもあります。ご了承のほど、お願いします。

データリソース社はどのような会社ですか?

当社は、世界各国の主要調査会社・レポート出版社と提携し、世界各国の市場調査レポートや技術動向レポートなどを日本国内の企業・公官庁及び教育研究機関に提供しております。

世界各国の「市場・技術・法規制などの」実情を調査・収集される時には、データリソース社にご相談ください。

お客様の御要望にあったデータや情報を抽出する為のレポート紹介や調査のアドバイスも致します。

|

|