Flexible & Printed Electronics 2023-2033: Forecasts, Technologies, Marketsフレキシブル&プリンテッドエレクトロニクス2023-2033年:予測、技術、市場 この調査レポートでは、2023-2033年の完全積層3Dエレクトロニクスからインモールドエレクトロニクス、新たなデジタル印刷法まで、さまざまな製造イノベーションとその展望について詳細に調査・分析しています... もっと見る

※ 調査会社の事情により、予告なしに価格が変更になる場合がございます。

Summary

この調査レポートでは、2023-2033年の完全積層3Dエレクトロニクスからインモールドエレクトロニクス、新たなデジタル印刷法まで、さまざまな製造イノベーションとその展望について詳細に調査・分析しています。

主な掲載内容(目次より抜粋)

Report Summary

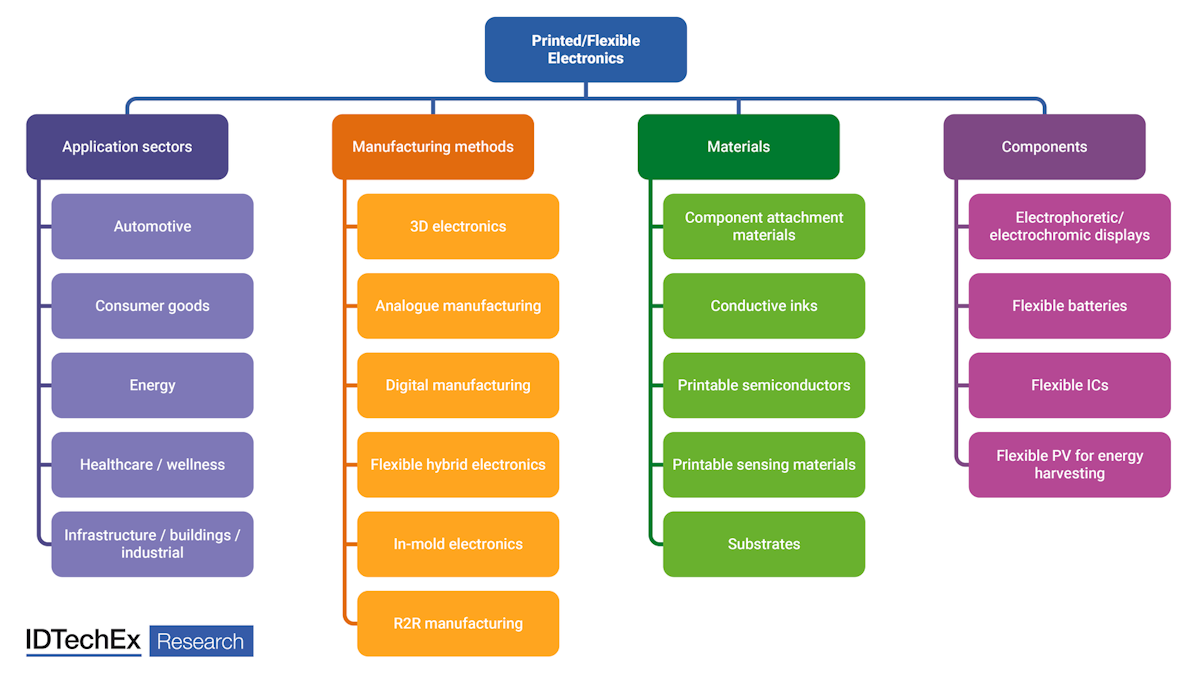

'Flexible & Printed Electronics 2023-2033: Forecasts, Technologies, Markets' explores and evaluates the trends and innovations across this emerging approach to electronics. By summarizing IDTechEx's extensive printed/flexible electronics report portfolio, and drawing on years of following this developing industry, the report outlines innovations, opportunities, and trends across 5 sectors of the printed and flexible electronics market: automotive, consumer goods, energy, healthcare/wellness, and infrastructure/buildings/industrial. This analysis includes granular forecasts of 50 distinct applications.

Additionally, the report outlines developments across multiple aspects of the printed and flexible electronics market: 6 distinct manufacturing modalities (including in-mold electronics and flexible hybrid electronics), 5 material types (including conductive inks and component attachment materials) and 4 component types (including flexible ICs). Multiple examples showing technology development directions and successful commercialization are provided, along with assessments of technological and commercial readiness. Additional forecasts for manufacturing methods and conductive inks are also provided.

Motivation for printed/flexible electronics

Conventional electronics manufacturing, in which copper laminate is selectively etched to leave conductive traces on a PCB (printed circuit board), is a well-established and ubiquitous technology. So why is printed/flexible electronics needed?

Arguably the main benefits are the flexible (and potentially stretchable) form factor combined with the ability to produce large areas. While flexible PCBs using etched copper laminate on a polyimide substrate are an established approach, components are often mounted on 'rigid islands' using standard sheet-to-sheet methods.

Application opportunities

As with conventional PCBs, printed and flexible electronics finds applications in many market verticals. The report forecasts the market for each of 5 verticals, with further segmentation by specific application. Illustrative examples showcase the most commercially promising and innovative applications, while the status and prospects of the underlying applications are illustrated.

The flexibility and stretchability of printed/flexible electronics makes the technology extremely well suited to wearable applications. Electronics skin patches utilizing conductive inks for electrodes and contacts are already available, as are printed pressure sensitive insoles for gait monitoring.

Another application sector seeing extensive traction is automotive interiors, which is increasingly regarded as an opportunity for differentiation. Printed/flexible electronics is well suited to producing large area, conformal functionality to enable integrated touch sensing, heating, and lighting.

Improving sustainability is of course a driver for many emerging technologies, and printed electronics is not different. After some challenging years organic photovoltaics is seeing a renaissance, with

Topics included within the 'Flexible & Printed Electronics 2023-2033: Forecasts, Technologies, Markets'. Source IDTechEx

Manufacturing methods

The benefits of printed/flexible electronics go beyond enabling new applications. It is a fundamentally different approach to manufacturing, replacing subtractive removal of laminated copper with additive deposition of conductive ink. This reduces waste and facilitates digital manufacturing with the associated benefits of rapid prototyping and straightforward design adjustments.

The report evaluates a range of manufacturing innovations and their prospects, ranging from fully additive 3D electronics to in-mold electronics and emerging digital printing methods. This includes notable examples, benefits and challenges, and

Material innovations

Material innovations underpin many emerging hardware technologies, and printed electronics is no exception. Conductive inks underpin the technology, with dozens of companies developing inks with a range of compositions and attributes. Viscous silver-flake based ink for screen printing dominates, but alternatives such as nano-particle and particle-free inks are gaining traction for specific applications such as EMI shielding. An especially notable trend is the development of copper ink, which promises a substantial cost reduction over its silver counterparts. This has long been an aspiration, but technical developments have largely resolved difficulties with oxidation leaving copper inks on the verge of commercial adoption.

Other specialty materials also play an important role in enabling printed/flexible electronics. For example, emerging component attachment materials such as ultra-low temperature solder and field-aligned anisotropic conductive adhesives enable components such as LEDs to be securely attached to cheaper, thermally fragile substrates. Furthermore, many sensors require specialist materials, such as printable piezoelectric polymers for vibration sensing and functionalized carbon nanotubes for ion detection.

Flexible components

While the original vision for printed and flexible electronics was to print every aspect of the circuit, including the integrated circuit, this has largely been supplanted by flexible hybrid electronics (FHE). This approach accepts that printed logic will struggle to compete with silicon, instead aiming for the 'best of both worlds' by printing conductive traces and potentially components such as sensors while mounting integrated circuits.

Of course, mounting rigid components compromises the thin-film flexible form factor to some extent, especially for larger components. As such, there is an opportunity for flexible ICs, batteries, displays and even some sensors that are manufactured independently and then mounted onto flexible substrates.

As with much of the functionality within flexible electronics, the emphasis is generally on achieving a flexible form factor, reducing costs, and improving sustainability rather than optimizing conventional performance metrics. For example, flexible metal oxide ICs can help reduce the costs of RFID tags, and in the future add more functionality for smart packaging applications.

Building on expertise

IDTechEx has been researching developments in the printed and flexible electronics market for well over a decade. Since then, we have stayed close to technical and commercial developments, interviewing key players worldwide, annually attending conferences such as FLEX and LOPEC, delivering multiple consulting projects, and running classes/ workshops on the topic. 'Flexible & Printed Electronics 2023-2033: Technologies, Markets, Forecasts' utilizes this experience and expertise to summarize IDTechEx's knowledge and insight across the entire field.

Table of Contents

|