Summary

この調査レポートは、フレキシブル電池、プリンテッド電池、薄膜電池市場を調査し、主要応用市場で使用される薄膜固体電池、定電流固体電池、先進リチウムイオン電池、一時リチウムイオン電池、亜鉛炭素電池、銀亜鉛電池について言及しています。

Description

The battery market has suddenly become alive again in recent years. On one hand, batteries are moving to new form factors, becoming ultra-thin, flexible, rollable, stretchable, etc. On the other hand, manufacturers are scrambling to offer large batteries aimed at addressing the large-sized electric vehicle, residential and grid applications. This market study is focused on the former.

The new batteries can be described from several dimensions including:

-Footprints (micro-batteries or large-area batteries),

-Thickness (thin-film or bulky batteries),

-Mechanical properties (flexibility, bendability, rollability, stretchability, foldability, etc.)

-Manufacturing methods (e.g. printing, coating, etc.) and

-Technologies (e.g. solid-state batteries, lithium-polymer batteries, carbon-zinc batteries, etc.)

IDTechEx has been tracking flexible, thin-film, printed batteries with above-mentioned angles since 2014. This report will provide technology development, market progress, application areas, current status, future trends & opportunities and global player activities with assessment and analysis.

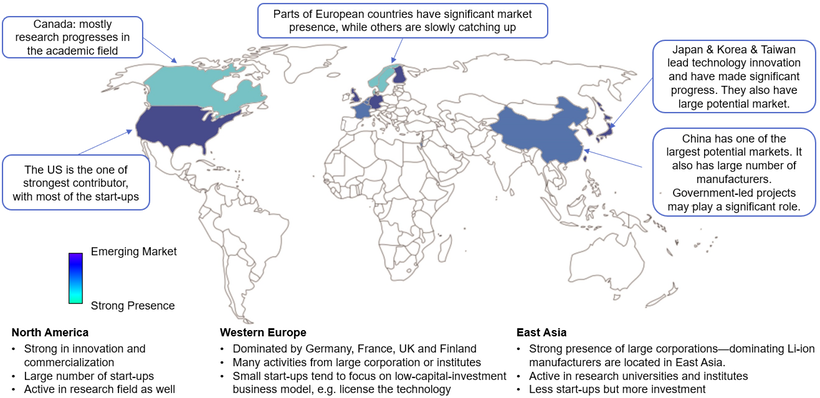

Figure 1: Market descriptions by territory

Source: IDTechEx

Flexible, thin and/or printed batteries (or batteries with novel form factors) are back on the agenda thanks to the rise of Internet of Things, wearables and environmental sensors. These applications require new features and battery designs that traditional battery technologies simply cannot provide. This has opened the door to innovation and added a new dimension to the global competition between battery suppliers.

Transforming industry

This is a fast-changing industry, with its technologies in a state of rapid progress as new designs, methods and modified chemistries are frequently announced. The business landscape is also being dramatically altered as many companies are now gearing up to progress their lab scale technologies into mass production. These are exciting years for this emerging technology.

The composition of the target market is undergoing drastic change, driven by the emergence of new addressable market categories. Traditionally, the micro-power thin and printed batteries were used in skin patches, RFID tags and smart cards. Today, however, many new emerging applications have appeared, enticing many large players to enter the foray and thus transforming a business landscape that was once populated predominantly by small firms.

IDTechEx provides detailed technology assessment and benchmarking, ten-year market forecasts segmented by application and technology type, and detailed interview-based business intelligence and profiles on key players and large end-users.

In this study IDTechEx has drawn upon at least 27 direct interviews and visits with key suppliers and large end-users from a variety of sectors and years of accumulated experience and market knowledge for the end use applications such as active RFIDs, smart cards, skin patches, smart packaging and recently wearables and IoT. Our team working on this project is highly technical, enabling it to fully understand the merits and challenges of each technology in this complex landscape.

Complex landscape to navigate

The market and technology landscape are complex. There are no black-and-white or clear technology winners and the definition of market requirements is in a constant state of flux.

Indeed, on the technology side, there are many solutions that fall within the broad category of thin film, flexible or printed batteries. These include printed batteries, thin-film batteries, advanced lithium-ion batteries, solid-state batteries, micro-batteries, stretchable batteries, thin flexible supercapacitors and a few more. It is therefore a confusing technology landscape to navigate and betting on the right technology is not straightforward.

On the market side, many applications are still emerging, and the requirements are fast evolving. The target markets are also very diverse and not overlapping, each with different requirements for power, lifetime, thinness, cost, charging cycles, reliability, flexibility, etc. This diversity of requirements means that no thin film battery offers a one-size-fits-all solution.

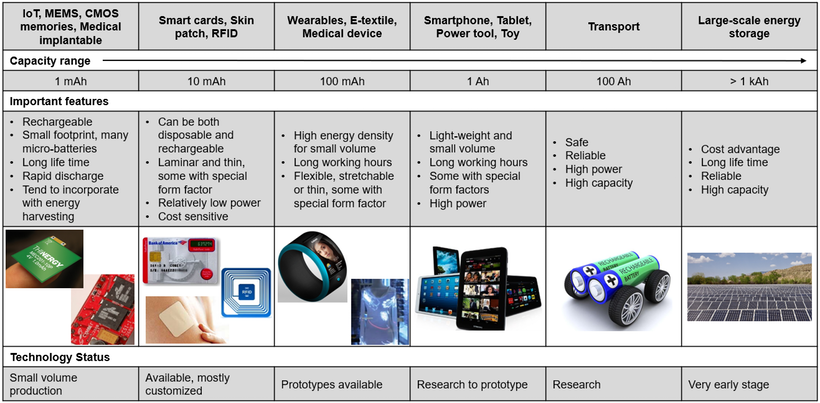

Figure 2: Applications of batteries with new form and structural factors

Source: IDTechEx

Applications

Wearable technology and electronic textiles are a major growth area for thin film and flexible batteries. Conventional secondary batteries may meet the energy requirements of wearable devices, but they struggle to achieve flexibility, thinness and light weight. These new market requirements open up the space for energy storage solutions with novel form factors. Indeed, the majority of thin-film battery companies tell us that they have on-going projects in the wearable technology field. High-energy thin film batteries have the highest potential here followed by printed rechargeable zinc batteries, provided the latter can improve.

The healthcare sector is also a promising target market. Skin patches using printed batteries are already a commercial reality, while IDTechEx anticipates that the market for disposable medical devices requiring micro-power batteries will also expand. This is a hot space as the number of skin patch companies is rapidly rising. Here, printed zinc batteries have the highest potential but price needs to continue falling before a higher market uptake takes place. Here too, new form factors will be the key differentiator, compared to the high-volume incumbents such as coin cell batteries. Medical diagnostic devices, medical sensors are also promising markets, although the current thin battery technology is not mature enough yet to be applied straightaway.

Connected device applications is another important trend especially combining special form factor and harsh temperature requirements. Here, there is a trend to combine energy harvesting with thin batteries with superior form factors.

Active and battery-assisted passive RFID is also a potential target market, although coin-cells are the main solutions unless there is a stringent requirement for laminar or flexible design such as in car plates. It is also in these small niches that thin film batteries might find a place.

Smart cards also remain an attractive sector and several thin-film battery technologies have been optimised to meet the lamination requirements for card manufacture. The price is however too steep to enable widespread market penetration. The emergence of online and mobile banking carries a long-term threat of substitution.

Technology assessment

IDTechEx provides a detailed assessment of all the key energy storage technologies that fall under the broad category of thin film, flexible or printed batteries. It provides a critical and quantitative analysis and benchmarks different solutions.

Market forecasts

IDTechEx has developed detailed and granular market forecasts segmented by technology type as well as end use applications. These forecasts are based on (a) primary information obtained through our direct interview programme with suppliers and end-users, attending conferences globally and also organising our own conferences on wearable technologies, RFIDs and printed electronics; and (b) a critical technical assessment of competing technologies.

The technologies and end use applications covered are:

End-uses

-

Wrist-worn wearables

-

Foot-worn wearables

-

Other wearables

-

Skin patch

-

Smart phone

-

Power bank/Power case

-

RFID

-

Smart packaging

-

Smart card

-

Connected devices

-

Backup power

-

Interactive Media, Toys, Games, Cards

-

Others

Technologies included in this report:

-

LiPON-based

-

Stackable thin-film battery

-

2D and 3D Micro-battery

-

Primary Li/CFx micro-battery

-

Flexible lithium-ion battery

-

Thin and flexible alkaline battery

-

Lithium manganese disposable battery

-

Laminated packaged lithium-polymer cells

-

Batteries with highly conductive polymer gel electrolyte

-

Solid-state battery

-

Cable-type battery

-

Large-area multi-stacked textile battery

-

Stretchable battery

-

Foldable Kirigami lithium-ion battery

-

Fibre-shaped lithium-ion battery that can be woven into electronic textiles

-

Printed zinc-carbon disposable battery

-

Printed silver zinc battery

-

Printed rechargeable NMH battery

-

Needle battery

-

Transparent battery

-

Laminar fuel cells

-

Thin and flexible supercapacitor

-

Printed supercapacitors

With a special focus and analysis on:

-

Thin-film solid-state battery

-

Bulk solid-state battery

-

Advanced lithium-ion battery

-

Primary lithium-based battery

-

Zinc-carbon battery

-

Silver zinc battery

ページTOPに戻る

Table of Contents

Table of Contents

|

1. |

EXECUTIVE SUMMARY AND CONCLUSIONS |

|

1.1. |

Overview |

|

1.2. |

Thin-film, flexible, printed batteries, and beyond |

|

1.3. |

Structure of the report |

|

1.4. |

Who should read this report |

|

1.5. |

Research methodology |

|

1.6. |

Thin, flexible and printed batteries are describing different aspects of battery features |

|

1.7. |

Technologies included in the report |

|

1.8. |

Technology benchmarking |

|

1.9. |

Future Direction of Battery Development |

|

1.10. |

Status of battery markets |

|

1.11. |

Major drivers for the development of new-form-and-structural-factor batteries |

|

1.12. |

Development roadmap of batteries |

|

1.13. |

Application market roadmap |

|

1.14. |

Business model |

|

1.15. |

A practical battery is a combination of many considerations |

|

1.16. |

Status of flexible batteries |

|

1.17. |

Value proposition |

|

1.18. |

Price perspectives |

|

1.19. |

Other challenges and difficulties |

|

1.20. |

Strategies for battery providers focusing on new form and structural factors |

|

1.21. |

Market by territory |

|

1.22. |

Market forecast assumptions |

|

1.23. |

Market forecast 2020-2030 by technology (unit) |

|

1.24. |

Market forecast 2020-2030 by technology (value) |

|

1.25. |

Market forecast 2020-2030 by application (units) |

|

1.26. |

Market forecast 2020-2030 by application (value) |

|

1.27. |

Market by application in 2020 and 2030 |

|

1.28. |

Analysis of battery technologies |

|

1.29. |

Analysis of application markets |

|

1.30. |

Conclusions |

|

2. |

APPLICATIONS |

|

2.1. |

Introduction to Applications |

|

2.1.1. |

Applications of battery with new form and structural factors |

|

2.1.2. |

Power range for electronic and electrical devices |

|

3. |

WEARABLES: STAGNATING? |

|

3.1.1. |

The growth of wearables |

|

3.1.2. |

Changes towards wearable devices |

|

3.1.3. |

Batteries are the main bottleneck of wearables |

|

3.1.4. |

Wearables at different locations of a human body |

|

3.1.5. |

Wearables: smart watch, wristband and bracelet |

|

3.1.6. |

Battery requirements |

|

3.1.7. |

Wrist-worn application examples with flexible batteries 1 |

|

3.1.8. |

Wrist-worn application examples with flexible batteries 2 |

|

3.1.9. |

Wrist-worn application examples with flexible batteries 3 |

|

3.1.10. |

Wrist-worn application examples with flexible batteries 4 |

|

3.1.11. |

Ankle/foot-worn application examples |

|

3.1.12. |

Head/eye-worn application examples |

|

3.1.13. |

Electronic apparel: gloves and textiles |

|

3.1.14. |

Military |

|

3.1.15. |

Other wearable application examples |

|

3.1.16. |

Summary and conclusions for wearable applications |

|

4. |

MEDICAL AND COSMETIC: HUGE OPPORTUNITIES? |

|

4.1. |

Mobile healthcare: Huge growth potential |

|

4.2. |

Cosmetic skin patches |

|

4.3. |

Iontophoresis for cosmetics |

|

4.4. |

Cardiovascular monitoring patch |

|

4.5. |

Wireless inpatient monitoring |

|

4.6. |

Temperature monitoring |

|

4.7. |

Life Science Technology |

|

4.8. |

Conformal displacement sensor |

|

4.9. |

Printed battery used in COVID-19 |

|

4.10. |

Medical skin patches - the dark horse |

|

4.11. |

A list of increasing number of medical skin patch products |

|

4.12. |

Medical implants 1 |

|

4.13. |

Medical implants 2 |

|

4.14. |

Medical implants 3 |

|

5. |

CONSUMER ELECTRONICS: WHAT NEXT? |

|

5.1. |

Future trend in battery for consumer electronics |

|

5.2. |

Flexibility: Big giants' growing interest |

|

5.3. |

Thinness is still required for now and future |

|

5.4. |

Slim consumer electronics |

|

5.5. |

New market: Thin batteries can help to increase the total capacity |

|

5.6. |

Battery case ideas |

|

5.7. |

Will modular phones be the direction of the future? |

|

5.8. |

Thin and flexible supercapacitor for consumer electronics |

|

5.9. |

Flexible phone may require other flexible components in the future |

|

6. |

FROM SENSORS TO INTERNET OF THINGS |

|

6.1. |

Something new vs renamed world of mobile phones |

|

6.2. |

Internet of Things |

|

6.3. |

Batteries for IoT |

|

6.4. |

Power supply options for WSN |

|

6.5. |

Rod-shape battery - examples |

|

6.6. |

Novel examples of thin batteries in IoT devices |

|

6.7. |

Golf sensor patch powered by printed battery |

|

6.8. |

Smart device powered by solid-state battery |

|

6.9. |

Thoughts about thin and flexible batteries in novel devices |

|

6.10. |

Maintenance-free wireless power for the IoT: Ready or not? |

|

6.11. |

Micro-batteries integrated with energy harvesting devices |

|

6.12. |

Real time clock backup, SRAM backup and microcontroller (MCU) |

|

6.13. |

RFID sensors/ tags with thin batteries |

|

6.14. |

Examples of thin batteries used in RFID tags/ sensors |

|

7. |

SMART PACKAGING AND ADVERTISING |

|

7.1. |

Smart packaging and advertising examples |

|

7.2. |

Audio Paper™ developed by Toppan Printing |

|

7.3. |

Case studies of power for smart packaging |

|

8. |

POWERED SMART CARDS |

|

8.1. |

Where will the powered smart cards go? |

|

8.2. |

Arrangement of batteries in smart cards |

|

8.3. |

Battery alternative solution |

|

8.4. |

Changes in smart card field |

|

9. |

OTHER MARKETS |

|

9.1. |

Application examples |

|

9.2. |

Printed batteries for other disposable applications? |

|

10. |

THIN FILM BATTERIES |

|

10.1. |

Introduction |

|

10.1.1. |

Typical thicknesses of the traditional battery components |

|

10.1.2. |

Design differences between thin-film batteries and bulk-size batteries |

|

10.1.3. |

Areal energy density vs. cell thickness |

|

10.1.4. |

Shortcomings of thin-film batteries |

|

10.1.5. |

Units used to characterize thin-film batteries |

|

10.1.6. |

Comparison of various solid-state lithium-based batteries |

|

10.1.7. |

Thin-film batteries from FDK |

|

10.2. |

Solid-state thin-film lithium battery |

|

10.2.1. |

Most successful commercial thin-film battery |

|

10.2.2. |

Players worked and working on thin-film lithium batteries |

|

10.2.3. |

Construction of an ultra-thin lithium battery |

|

10.2.4. |

Cathode material options for thin-film batteries |

|

10.2.5. |

Cathode of thin film lithium battery |

|

10.2.6. |

Anode of thin film lithium battery |

|

10.2.7. |

Substrate options |

|

10.2.8. |

Advantages and disadvantages of selected materials |

|

10.2.9. |

Trend of materials and processes of thin-film battery in different companies |

|

10.2.10. |

Ultra-thin micro-battery—NanoEnergy® |

|

10.2.11. |

Micro-Batteries suitable for integration |

|

10.2.12. |

From limited to mass production—STMicroelectronics |

|

10.2.13. |

Summary of the EnFilm™ rechargeable thin-film battery |

|

10.2.14. |

CEA Tech |

|

10.2.15. |

TDK |

|

10.2.16. |

CeraCharge's performance |

|

10.2.17. |

Main applications of CeraCharge |

|

10.2.18. |

NGK |

|

10.2.19. |

NGK's EnerCerachip |

|

10.2.20. |

Thin-film solid-state batteries made by Excellatron |

|

10.2.21. |

Johnson Battery Technologies |

|

10.2.22. |

JBT's advanced technology performance |

|

10.2.23. |

LiPON: capacity increase |

|

10.2.24. |

Technology of Infinite Power Solutions |

|

10.2.25. |

Cost comparison between a standard prismatic battery and IPS' battery |

|

10.3. |

Manufacturing approaches of solid-state thin-film lithium batteries |

|

10.3.1. |

Summary of main fabrication technique for thin film batteries |

|

10.3.2. |

PVD processes for thin-film batteries 1 |

|

10.3.3. |

PVD processes for thin-film batteries 2 |

|

10.3.4. |

PVD processes for thin-film batteries 3 |

|

10.3.5. |

Direct vapor deposition for thin-film batteries |

|

10.3.6. |

Thin-film battery potentials |

|

11. |

BATTERY SIZE REDUCTION: MICRO-BATTERIES |

|

11.1. |

Architectures of micro-batteries |

|

11.2. |

Introduction to micro-batteries |

|

11.3. |

3D printed lithium-ion micro-batteries |

|

11.4. |

Primary Li/CFx micro-battery |

|

12. |

BATTERIES WITH SPECIAL MECHANICAL PROPERTIES: FLEXIBLE, STRETCHABLE, ROLLABLE, BENDABLE AND FOLDABLE BATTERIES |

|

12.1.1. |

Flexible electronics |

|

12.1.2. |

Realization of batteries' mechanical properties 1 |

|

12.1.3. |

Realization of batteries' mechanical properties 2 |

|

12.2. |

Thickness-derived flexibility |

|

12.2.1. |

Stresses generated in a the battery during flexing |

|

12.2.2. |

A thin battery is usually flexible to some extent |

|

12.3. |

Material-derived flexibility |

|

12.3.1. |

Comparison of a flexible LIB with a traditional one |

|

12.3.2. |

Material choices for different battery components |

|

12.4. |

Efforts on the electrolyte/ separator |

|

12.4.1. |

Solid-state electrolyte |

|

12.4.2. |

Safety of solid-state batteries |

|

12.4.3. |

Improvement of solid-state battery |

|

12.4.4. |

Comparison of organic and inorganic solid-state electrolyte |

|

12.4.5. |

Polymer-based electrolytes |

|

12.4.6. |

Bendable lithium-based battery |

|

12.4.7. |

Lionrock Batteries |

|

12.4.8. |

Highly conductive polymer gel electrolyte and lamination processes for roll-to-roll Li-ion cell production |

|

12.4.9. |

BrightVolt batteries |

|

12.4.10. |

BrightVolt product matrix |

|

12.4.11. |

Electrolyte |

|

12.4.12. |

Toes Opto-Mechatronics |

|

12.4.13. |

Hitachi Zosen's solid-state electrolyte |

|

12.4.14. |

Hitachi Zosen's batteries |

|

12.4.15. |

Hitachi Maxell |

|

12.4.16. |

Lithium ion conducting glass-ceramic powder-01 |

|

12.4.17. |

LICGCTM PW-01 for cathode additives |

|

12.4.18. |

Ohara's products for solid state batteries |

|

12.4.19. |

Ohara / PolyPlus |

|

12.4.20. |

Application of LICGC for all solid state batteries |

|

12.4.21. |

Properties of multilayer all solid-state lithium ion battery using LICGC as electrolyte |

|

12.4.22. |

LICGC products at the show |

|

12.4.23. |

Manufacturing process of Ohara glass |

|

12.4.24. |

Planar Energy |

|

12.4.25. |

ProLogium: Solid-state lithium ceramic battery |

|

12.4.26. |

ProLogium |

|

12.4.27. |

LiPON-based solid-state batteries |

|

12.4.28. |

Ilika's stacked solid-state micro-battery 1 |

|

12.4.29. |

Ilika's stacked solid-state micro-battery 2 |

|

12.4.30. |

Ilika 3 |

|

12.4.31. |

Thin film vs. bulk solid-state batteries |

|

12.5. |

Efforts on the electrodes |

|

12.5.1. |

Innovative electrode |

|

12.5.2. |

From electrode innovation to flexible batteries |

|

12.6. |

Efforts on the current collectors |

|

12.6.1. |

Carbon materials for current collectors |

|

12.6.2. |

Thin and flexible alkaline battery developed by New Jersey Institute of Technology |

|

12.6.3. |

Flexible battery achieved by anode materials |

|

12.7. |

Efforts on the packaging |

|

12.7.1. |

Lithium-polymer pouch cells |

|

12.7.2. |

Techniques to fabricate aluminium laminated sheets |

|

12.7.3. |

Packaging procedures for pouch cells 1 |

|

12.7.4. |

Packag

ページTOPに戻る

本レポートと同分野(プライマリケア)の最新刊レポート

IDTechEx社のウエアラブル技術 - Wearable Technology分野での最新刊レポート

本レポートと同じKEY WORD()の最新刊レポート

- 本レポートと同じKEY WORDの最新刊レポートはありません。

よくあるご質問

IDTechEx社はどのような調査会社ですか?

IDTechExはセンサ技術や3D印刷、電気自動車などの先端技術・材料市場を対象に広範かつ詳細な調査を行っています。データリソースはIDTechExの調査レポートおよび委託調査(個別調査)を取り扱う日... もっと見る

調査レポートの納品までの日数はどの程度ですか?

在庫のあるものは速納となりますが、平均的には 3-4日と見て下さい。

但し、一部の調査レポートでは、発注を受けた段階で内容更新をして納品をする場合もあります。

発注をする前のお問合せをお願いします。

注文の手続きはどのようになっていますか?

1)お客様からの御問い合わせをいただきます。

2)見積書やサンプルの提示をいたします。

3)お客様指定、もしくは弊社の発注書をメール添付にて発送してください。

4)データリソース社からレポート発行元の調査会社へ納品手配します。

5) 調査会社からお客様へ納品されます。最近は、pdfにてのメール納品が大半です。

お支払方法の方法はどのようになっていますか?

納品と同時にデータリソース社よりお客様へ請求書(必要に応じて納品書も)を発送いたします。

お客様よりデータリソース社へ(通常は円払い)の御振り込みをお願いします。

請求書は、納品日の日付で発行しますので、翌月最終営業日までの当社指定口座への振込みをお願いします。振込み手数料は御社負担にてお願いします。

お客様の御支払い条件が60日以上の場合は御相談ください。

尚、初めてのお取引先や個人の場合、前払いをお願いすることもあります。ご了承のほど、お願いします。

データリソース社はどのような会社ですか?

当社は、世界各国の主要調査会社・レポート出版社と提携し、世界各国の市場調査レポートや技術動向レポートなどを日本国内の企業・公官庁及び教育研究機関に提供しております。

世界各国の「市場・技術・法規制などの」実情を調査・収集される時には、データリソース社にご相談ください。

お客様の御要望にあったデータや情報を抽出する為のレポート紹介や調査のアドバイスも致します。

|

|