Summary

金属による付加製造(積層造形)産業の収益は、2019年の14億ドルから、2027年には54億ドルに達すると予測している。米国調査会社スマーテックマーケッツパブリッシング(SmarTech Markets Publishing)の調査レポート「コンパクト産業用金属付加製造(積層造形)プリンタのビジネスチャンス 2019年」は、この市場の中でも比較的安価な価格帯で利用しやすいものでありながら、産業レベルの製造品質を提供することのできる金属プリンタの市場セグメントについて調査している。新しい産業ユーザにとって、金属3D印刷技術が採用しやすいものとなるだろう。

金属による付加製造(積層造形)産業の収益は、2019年の14億ドルから、2027年には54億ドルに達すると予測している。米国調査会社スマーテックマーケッツパブリッシング(SmarTech Markets Publishing)の調査レポート「コンパクト産業用金属付加製造(積層造形)プリンタのビジネスチャンス 2019年」は、この市場の中でも比較的安価な価格帯で利用しやすいものでありながら、産業レベルの製造品質を提供することのできる金属プリンタの市場セグメントについて調査している。新しい産業ユーザにとって、金属3D印刷技術が採用しやすいものとなるだろう。

Compact Industrial Metal AM Printer Market Opportunities 2019

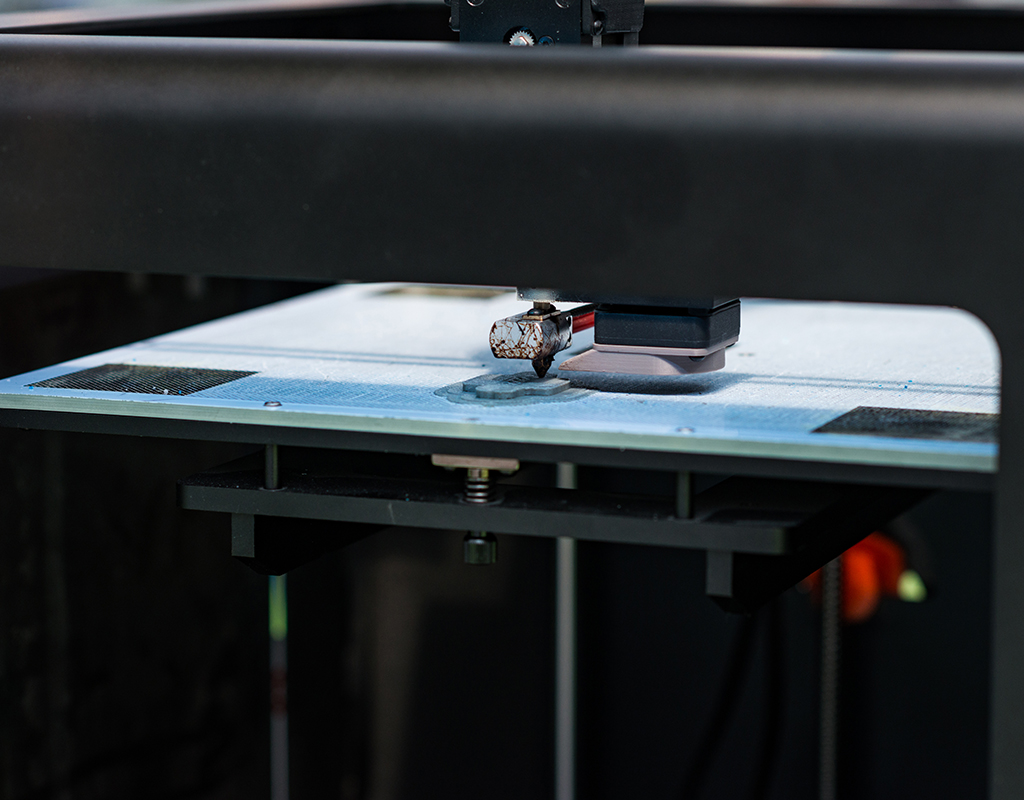

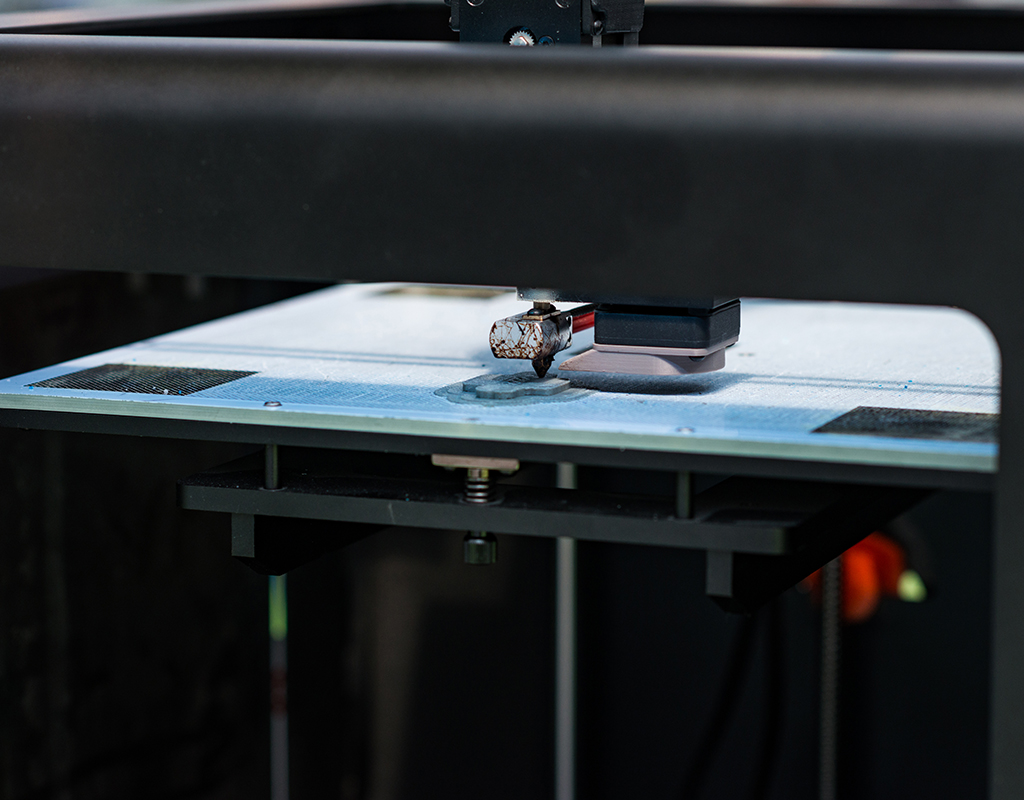

The metal additive manufacturing industry is estimated to generate $1.4 billion in revenues in 2019, growing to $5.4 billion by 2027. Within this industry is a relatively new sub-segment of metal printers that introduces a more accessible price-point and shorter learning curve, while still offering industrial-level production and quality. We’ve identified this sub-segment as Compact Industrial Metal AM Printers and it addresses a significant hole in the marketplace and creates a lower-level entry point for new industrial users of metal 3D printing technology.

As the leading provider of metal based additive manufacturing market analysis, SmartTech Analysis is pleased to introduce this new report covering an exciting new market.

The report includes:

-

The definition and market requirements for Compact Industrial Metal AM Printers.

-

The applications within any given product lifecycle as well as within the primary industrial verticals, such as automotive, medical & dental, and general manufacturing.

-

A general overview of the hardware technologies, with things to consider and the pros and cons of each.

-

A detailed review of each of the current notable manufacturers of Compact Industrial Metal AM Printers.

-

A detailed analysis of the current state of the Compact Industrial Metal AM Printers market and forecasts through 2027, to include analyses of revenues, installations and market share by market, technology, and manufacturer.

-

A discussion on cost of ownership of the various technologies, primary developments for consideration, and obstacles to adoption.

People that might this report useful include:

-

Machine shops looking to invest in metal 3D printing / additive manufacturing technology.

-

Companies looking to acquire up & coming metal 3D printing hardware technology companies.

-

Manufacturers who already own plastic 3D printing hardware and are looking to add metal 3D printing to their portfolio.

-

Entrepreneurial hardware companies looking for opportunities within the fast-growing metal 3D printing market.

-

Service bureaus looking to expand on their existing capabilities with lower cost, high-quality printing metal printing.

ページTOPに戻る

Table of Contents

Chapter One: Introduction

1.1 Background and Objective

1.2. Definition and Requirements

1.2.1 Accessibility

1.2.2 Speed and Quality

1.2.3 Applicability

1.2.4 Cost

1.2.5 Summary

Chapter Two: Applications of Compact Industrial Metal 3D Printers

2.1 Applications Within the Product Lifecycle

2.1.1 Applications in the Innovation Stage

2.1.2 Applications in the Growth Stage

2.1.3 Applications in the Production Stage

2.1.4 Applications in the Decline Stage

2.2 Applications by Vertical

2.2.1 Applications within Automotive

2.2.2 Applications within Aerospace

2.2.3 Applications within Medical and Dental

2.2.4 Application within General Industrial Manufacturing

2.2.5 Application within Service Bureau

Chapter Three: Printer Technologies

3.1 Powder Bed Fusion (PBF)

3.2 Material Extrusion (ME)

3.3 Directed Energy Deposition (DED)

3.4 Summary

Chapter Four: Compact Industrial Metal Printer Manufacturers

4.1 Additec

4.2 Aurora Labs

4.3 Desktop Metal

4.4 Markforged

4.5 OR Laser / Coherent

4.6 Pollen AM

4.7 Xact Metal

4.8 Summary

4.9 Others

4.9.1 Airwolf 3D

4.9.2 Cytosurge

4.9.3 Evo-Tech

4.9.4 3d-Figo

4.9.5 InssTek

Chapter Five: The State of the Compact Industrial Metal 3D Printer Market

5.1 Metal Market Summary

5.2 Compact Industrial Metal Printers Market, Global Revenue and Market Share

5.2.1 Regional Markets

Chapter Six: Cost of Ownership

6.1 Hardware Costs

6.2 Material Costs

6.3 Post Processing Costs

Chapter Seven: Primary Developments and Obstacles to Adoption

7.1 Primary Developments During 2018 and Early 2019 Expected to Impact the Future

7.1.1 Desktop Metal Becomes the Highest Funded Private 3D Printing Company in History

7.1.2 Markforged Expands to Europe with a $82M Funding Round

7.1.3 Software and Connectivity Takes Center Stage

7.1.4 Xact Metal Makes Powder Bed Fusion More Accessible

7.2 Obstacles to Adoption

About SmarTech Analysis

About the Analyst

Acronyms and Abbreviations Used In this Report

List of Exhibits

Exhibit 1-1: Evaluation Criteria for Compact Industrial Metal Printers

Exhibit 1-2: Typical characteristics of Maker, Prosumer, compact industrial metal and High-End 3D Printing Solutions

Exhibit 1-3: Speed and Quality vs. Ease of Use for the Various Categories of Metal 3D Printers

Exhibit 1-4: Cost vs. Application/Customer-Base for the Various Categories of Metal 3D Printers

Exhibit 2-1: Applications for Compact Industrial Metal 3D Printers within Each Stage of a Product’s Lifecycle

Exhibit 2-2: Considerations for Applications by Printer Technology

Exhibit 2-3: Estimated Global Revenue for Compact Industrial Printers by Vertical Market, 2016-2027(e)

Exhibit 2-4: Estimated Global Revenue for Compact Industrial Printers by Within the Automotive Vertical by Technology, 2016-2027(e)

Exhibit 2-5: Estimated Global Revenue for Compact Industrial Printers by Within the Aerospace Vertical by Technology, 2016-2027(e)

Exhibit 2-6: Market Adoption Statistics for Metal Additively Manufactured Implants

Exhibit 2-7: Estimated Global Revenue for Compact Industrial Printers by Within the Medical/Dental Vertical by Technology, 2016-2027(e)

Exhibit 2-8: Estimated Global Revenue for Compact Industrial Printers by Within the General Engineering Vertical by Technology, 2016-2027(e)

Exhibit 2-9: Estimated Global Revenue for Compact Industrial Printers by Within Service Bureaus by Technology, 2016-2027(e)

Exhibit 3-1: Summary of Global AM Printer Revenues for Compact Industrial Metal Printers Utilizing Powder Bed Fusion (PBF), 2014 – 2027(e)

Exhibit 3-2: The BMD and ADAM processes by Markforged and Desktop Metal

Exhibit 3-3: Summary of Global AM Printer Revenues for Compact Industrial Metal Printers Utilizing Material Extrusion (ME), 2014 – 2027(e)

Exhibit 3-4: Summary of Global AM Printer Revenues for Compact Industrial metal printers utilizing Directed Energy Deposition (DED), 2014 – 2027(e)

Exhibit 3-5: Benefits and Limitations of Technologies Implemented for Compact Industrial Metal 3D Printers

Exhibit 4-1: A comparison within the Materials Extrusion (ME) Sub-Segment of Solutions

Exhibit 4-2: A Comparison within the Powder Bed Fusion (PBF) Sub-segment of Solutions

Exhibit 4-3: Summary Chart

Exhibit 5-1: Summary of Global AM Hardware Revenues, by Material Category

Exhibit 5-2: Percent of Global AM Hardware Revenues, by Material Category

Exhibit 5-3: Overall Metal AM Hardware Revenues as a Function of Technology (ME, PBF, DED)

Exhibit 5-4: Estimated Market Share, by Revenue, for Metal Additive Manufacturing Market by Printer Hardware Technology, 2019

Exhibit 5-5: Estimated Global Revenues for Compact Industrial Printer Hardware by Printer Technology, 2014-2027(e)

Exhibit 5-6: Estimated Summary of Global Compact Industrial Printer Hardware installations by Printer Technology, 2014-2027(e)

Exhibit 5-7: Estimated Global Market Share for Compact Industrial Printer Hardware by Printer Technology, 2014-2027(e)

Exhibit 5-8: Estimated Global Market Share for Compact Industrial Printer Hardware Based on Revenues by Vendor, 2019

Exhibit 5-9: Estimated Global Market Share for Compact Industrial Printer Hardware Based on Units by Vendor, 2019

Exhibit 5-10: Estimated Global Market Share for Compact Industrial Printer Hardware Based on Revenue by Region, 2019

Exhibit 5-11: Estimated Global Market share for Compact Industrial Printer Hardware Based on Revenue by Region and Technology, 2019 64

Exhibit 5-12: Estimated Global Revenue for Compact Industrial Printer Hardware by Region and Technology, 2019

Exhibit 6-1: Typical Costs for Metal Feedstock for PBF, ME and DED Compact Industrial Metal Printers

金属による付加製造(積層造形)産業の収益は、2019年の14億ドルから、2027年には54億ドルに達すると予測している。米国調査会社スマーテックマーケッツパブリッシング(SmarTech Markets Publishing)の調査レポート「コンパクト産業用金属付加製造(積層造形)プリンタのビジネスチャンス 2019年」は、この市場の中でも比較的安価な価格帯で利用しやすいものでありながら、産業レベルの製造品質を提供することのできる金属プリンタの市場セグメントについて調査している。新しい産業ユーザにとって、金属3D印刷技術が採用しやすいものとなるだろう。

金属による付加製造(積層造形)産業の収益は、2019年の14億ドルから、2027年には54億ドルに達すると予測している。米国調査会社スマーテックマーケッツパブリッシング(SmarTech Markets Publishing)の調査レポート「コンパクト産業用金属付加製造(積層造形)プリンタのビジネスチャンス 2019年」は、この市場の中でも比較的安価な価格帯で利用しやすいものでありながら、産業レベルの製造品質を提供することのできる金属プリンタの市場セグメントについて調査している。新しい産業ユーザにとって、金属3D印刷技術が採用しやすいものとなるだろう。