Summary

この調査レポートは、80エーカーズ、カレラ、クロップワンホールディングス、ジョーンズフード社の役員を含む業界全体の主要プレイヤー17名へのインタビューと30社以上のプロファイルに基づいて、垂直農業業界の現状を洞察し、業界が直面する課題と垂直農業企業を成功させるための要因について詳細に調査・分析しています。

主な掲載内容(目次より抜粋)

-

垂直農法の技術、課題、経済性

-

市場

-

予測

-

企業プロフィール

Report Summary

With a global population expected to reach 10 billion by 2050, paired with a decreasing amount of arable land caused by climate change and growing urbanisation, the agriculture industry faces major challenges over the coming years. To this end, vertical farms have attracted much interest over the last few years as a possible solution. By growing plants indoors under fully controlled environments in many stacked layers, using artificial lighting instead of the sun, vertical farms can tune their growing environments to the exact needs of the plant. When combined with soil-free growing techniques and high growing densities from their layout, vertical farming can achieve yields hundreds of times above that of conventional agriculture, 365 days a year and without requiring pesticides.

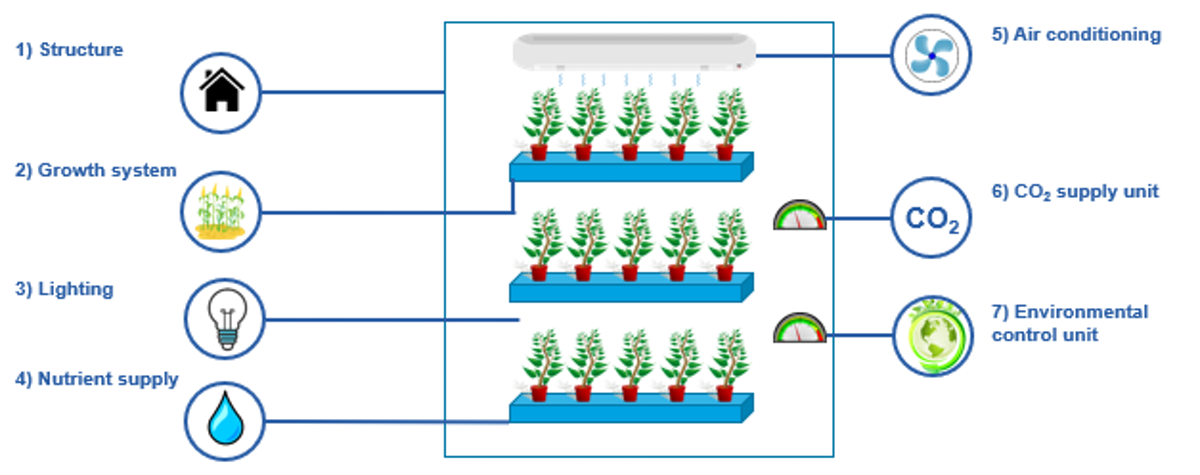

Vertical farms use a combination of sensors, HVACs and lighting systems to maintain a controlled environment. Source IDTechEx

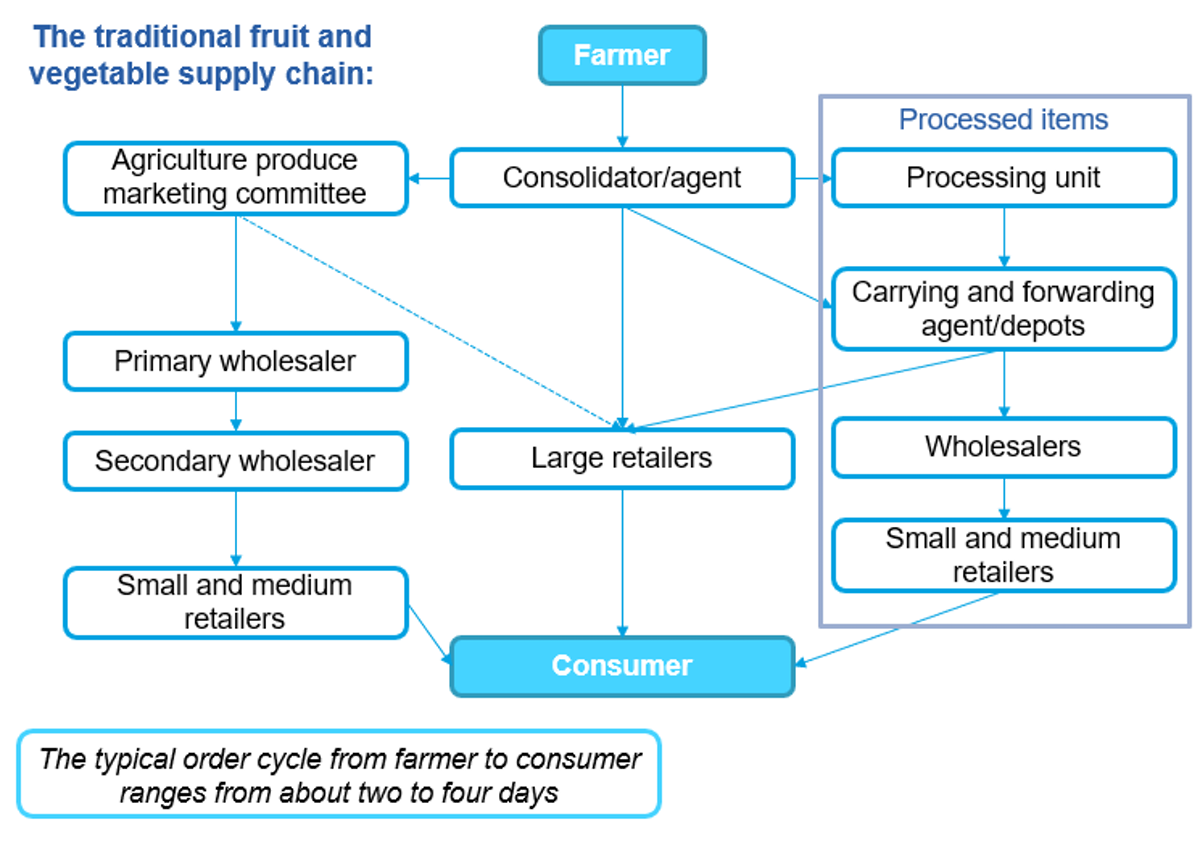

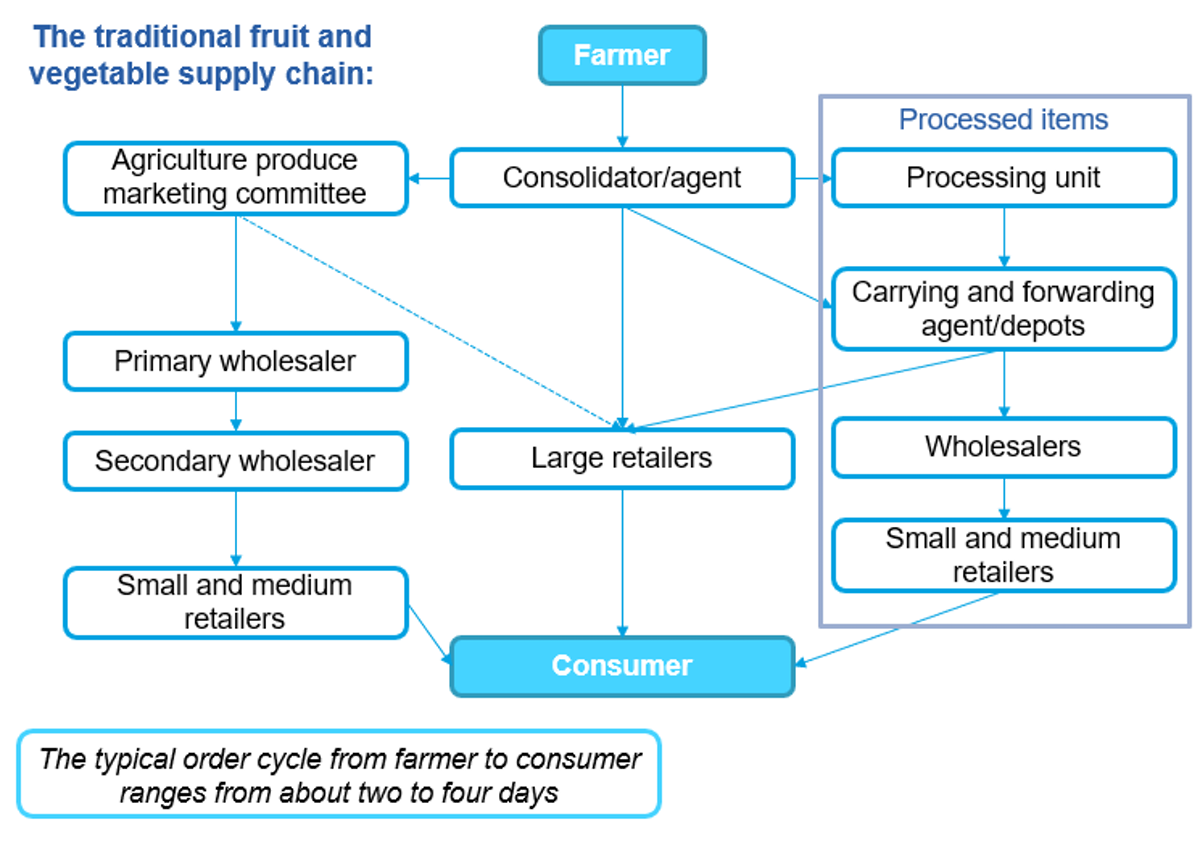

Supporters of vertical farming claim it could revolutionise global food production, practically eliminating food miles by enabling crop growth right next to urban population centres. Currently, fruit and vegetables often travel thousands of miles to reach consumers, losing freshness and quality along the way and increasing the risk of contamination. This has been a particular issue in the US, where recent E. coli outbreaks from contaminated produce have led to hundreds of hospitalisations in recent years. This has been further exacerbated by recent disruptions to the supply chain caused by the pandemic and geopolitical issues, highlighting concerns with a notoriously complex supply chain. By disrupting the highly centralised model for fresh produce, vertical farming could help overcome these issues, while capitalizing on the broader consumer trend towards local production.

The traditional agriculture market is associated with a notoriously complex supply chain, and vertical farms could simplify this drastically by cutting out several middlemen. Source IDTechEx

The vertical farming industry has attracted much interest from investors over the last few years. The industry raised over $1 billion in 2021, a record high that exceeded the combined funding generated in 2018 and 2019. Of note is California-based vertical farm Plenty, which has raised over $900 million in funding to date; this included $400 million in a 2022 Series E funding supported by retail giant Walmart and SoftBank Vision Fund. Across the Pacific, the industry is already well-established - in Japan there are over 200 vertical farms currently operating, with industry leader Spread Co. Ltd. producing 30,000 heads of lettuce every day in its highly automated Techno Farm Keihanna plant.

However, the industry is also facing many challenges. The sector is littered with bankruptcies - PodPonics and FarmedHere, once operators of the largest vertical farms in the world, closed their doors in 2016 after struggling with spiralling power and labour costs and organisational complexities. Part of these challenges are the high cost of crop production commonly associated with vertical farms. Maintaining a controlled environment requires a great deal of energy, and the use of artificial lighting over sunlight accounts for a large part of this energy usage. The running of a vertical farm can also require much manual labour often in environments not designed for growing crops (such as inside shipping containers); human intervention is required for many aspects within the farm, ranging from crop monitoring to system maintenance. The associated energy and labour costs can contribute significantly to the high prices associated with vertically farmed produce, which may discourage consumers from these products.

Nevertheless, enthusiasm remains high and technology is helping to decrease the costs of vertical farming and make large scale urban food production a reality. This report provides an in-depth discussion of the key technology areas that are helping to make vertical farming a reality, identifying areas that could be key to the success of the industry, such as:

-

Growing methods

-

LEDs and lighting

-

Environmental controls

-

Sensors

-

Automation

-

Container farming

Based on interviews with 17 major players throughout the sector, including executives from 80 Acres, Kalera, Crop One Holdings and Jones Food Company and profiles of over 30 companies, this report draws insight into the state of the vertical farming industry, discussing the challenges that the industry faces and the factors involved in creating a successful vertical farming company. The report considers the economics of vertical farming in comparison to conventional agriculture and identifies opportunities for players in the industry and the wider value chain.

The report goes on to describe the value chain for vertical farming, as well as business models and how the markets for vertical farming change across geographies, contrasting the rapidly emerging markets in North America with the established markets in East Asia. The report then forecasts the future of the vertical farming industry covering produce in key geographies and business types up to 2032.

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger

ページTOPに戻る

Table of Contents

Enable Ginger

|

1. |

EXECUTIVE SUMMARY |

|

1.1. |

Report overview |

|

1.2. |

The problem with agriculture |

|

1.3. |

Is vertical farming the answer? |

|

1.4. |

Components of a vertical farm |

|

1.5. |

Technologies: key findings |

|

1.6. |

Vertical farming: expectations vs reality |

|

1.7. |

Vertical farms: SWOT analysis |

|

1.8. |

Production and running costs (OPEX) of a vertical farm |

|

1.9. |

Challenges in vertical farming |

|

1.10. |

Vertical farming's struggle with profitability |

|

1.11. |

What crops do vertical farms grow? |

|

1.12. |

The effects of rising oil prices and supply chain disruptions |

|

1.13. |

Vertical farming facilities: better to go big or small? |

|

1.14. |

The vertical farming value chain |

|

1.15. |

The three main business models in vertical farming |

|

1.16. |

Investments in vertical farming |

|

1.17. |

Vertically farmed produce: global forecast |

|

2. |

INTRODUCTION |

|

2.1. |

Overview |

|

2.1.1. |

The problem with agriculture |

|

2.1.2. |

Is vertical farming the answer? |

|

2.1.3. |

How does vertical farming work? |

|

2.1.4. |

The case for vertical farming |

|

2.1.5. |

Drivers of vertical farming |

|

2.1.6. |

Challenges in vertical farming |

|

2.1.7. |

What crops can vertical farming grow? |

|

2.1.8. |

Vertical farming vs other production methods |

|

2.1.9. |

The definition of a vertical farm for this report |

|

2.2. |

Components of a vertical farm |

|

2.2.1. |

Structures |

|

2.2.2. |

Growing systems |

|

2.2.3. |

Lighting |

|

2.2.4. |

Nutrient supply: Hydroponics |

|

2.2.5. |

Nutrient supply: Aeroponics |

|

2.2.6. |

Nutrient supply: Aquaponics |

|

2.2.7. |

Air conditioning |

|

2.2.8. |

CO2 supply unit |

|

2.2.9. |

Environmental control units |

|

3. |

TECHNOLOGIES IN VERTICAL FARMING |

|

3.1. |

Overview |

|

3.1.1. |

What is needed for a vertical farm? |

|

3.2. |

Growing techniques |

|

3.2.1. |

Hydroponics vs aeroponics |

|

3.2.2. |

Aeroponics technologies |

|

3.2.3. |

AeroFarms |

|

3.2.4. |

How does AeroFarms' system work? |

|

3.2.5. |

LettUs Grow |

|

3.2.6. |

Vertical growth walls and towers |

|

3.2.7. |

Are vertical growth towers more efficient? |

|

3.2.8. |

Are vertical growth towers more efficient? |

|

3.2.9. |

Plenty |

|

3.2.10. |

Aquaponics: overview |

|

3.2.11. |

Historical precedents for aquaponics |

|

3.2.12. |

Upward Farms |

|

3.2.13. |

The trouble with aquaponics |

|

3.2.14. |

Reasons why aquaponics is often unprofitable |

|

3.2.15. |

The differences between aquaponics vertical farms and rice-fish farms |

|

3.2.16. |

How much fish can aquaponics farms produce? |

|

3.2.17. |

Are aquaponics systems economically viable? |

|

3.3. |

LEDs and lighting |

|

3.3.1. |

LEDs and photosynthesis |

|

3.3.2. |

Photosynthesis and yield |

|

3.3.3. |

Maximising photosynthesis |

|

3.3.4. |

Light "recipes" for indoor crop growth |

|

3.3.5. |

Light recipe has a major impact on the crop |

|

3.3.6. |

Choosing the right LEDs for a vertical farm |

|

3.3.7. |

Choosing LED grow lights for vertical farming |

|

3.3.8. |

Signify |

|

3.3.9. |

Signify GreenPower production module specifications |

|

3.3.10. |

LumiGrow |

|

3.3.11. |

Heliospectra |

|

3.3.12. |

Heliospectra's product families |

|

3.3.13. |

Improving LED technology and vertical farming |

|

3.3.14. |

Sherpa Space |

|

3.4. |

Environmental control |

|

3.4.1. |

Heating, ventilation and air conditioning (HVAC) |

|

3.4.2. |

Factors in HVAC systems |

|

3.4.3. |

The importance of sensors and data |

|

3.4.4. |

Where can sensors be used in a vertical farm? |

|

3.4.5. |

CO2 sensors are essential for vertical farms |

|

3.4.6. |

The importance of light sensors |

|

3.4.7. |

Light sensors - complete spectrum vs. multispectral |

|

3.4.8. |

Smart sensor companies in horticulture |

|

3.4.9. |

Aranet |

|

3.4.10. |

IDTechEx reports on sensors |

|

3.5. |

Automation in vertical farming |

|

3.5.1. |

Automation levels in vertical farming |

|

3.5.2. |

Automation is not yet widespread in vertical farming |

|

3.5.3. |

Technology adoption in vertical farming |

|

3.5.4. |

Industry leaders look towards increasing automation |

|

3.5.5. |

Automation: environmental control |

|

3.5.6. |

Autogrow |

|

3.5.7. |

Priva |

|

3.5.8. |

Automation: nutrient control |

|

3.5.9. |

Imagination Garden |

|

3.5.10. |

Automation: light recipes |

|

3.5.11. |

Bowery Farming |

|

3.5.12. |

Taking automation beyond level 2 |

|

3.5.13. |

Logiqs |

|

3.5.14. |

Is automation worth it? |

|

3.5.15. |

Intelligent Growth Solutions |

|

3.5.16. |

SananBio US |

|

3.5.17. |

Jones Food Company |

|

3.5.18. |

What could automation provide? - 1 |

|

3.5.19. |

What could automation provide? - 2 |

|

3.5.20. |

Automation and robotics in conventional agriculture |

|

3.6. |

Pests and diseases |

|

3.6.1. |

Pests and diseases |

|

3.6.2. |

Pest management |

|

3.6.3. |

Common diseases in vertical farming |

|

3.7. |

ページTOPに戻る

本レポートと同じKEY WORD()の最新刊レポート

- 本レポートと同じKEY WORDの最新刊レポートはありません。

よくあるご質問

IDTechEx社はどのような調査会社ですか?

IDTechExはセンサ技術や3D印刷、電気自動車などの先端技術・材料市場を対象に広範かつ詳細な調査を行っています。データリソースはIDTechExの調査レポートおよび委託調査(個別調査)を取り扱う日... もっと見る

調査レポートの納品までの日数はどの程度ですか?

在庫のあるものは速納となりますが、平均的には 3-4日と見て下さい。

但し、一部の調査レポートでは、発注を受けた段階で内容更新をして納品をする場合もあります。

発注をする前のお問合せをお願いします。

注文の手続きはどのようになっていますか?

1)お客様からの御問い合わせをいただきます。

2)見積書やサンプルの提示をいたします。

3)お客様指定、もしくは弊社の発注書をメール添付にて発送してください。

4)データリソース社からレポート発行元の調査会社へ納品手配します。

5) 調査会社からお客様へ納品されます。最近は、pdfにてのメール納品が大半です。

お支払方法の方法はどのようになっていますか?

納品と同時にデータリソース社よりお客様へ請求書(必要に応じて納品書も)を発送いたします。

お客様よりデータリソース社へ(通常は円払い)の御振り込みをお願いします。

請求書は、納品日の日付で発行しますので、翌月最終営業日までの当社指定口座への振込みをお願いします。振込み手数料は御社負担にてお願いします。

お客様の御支払い条件が60日以上の場合は御相談ください。

尚、初めてのお取引先や個人の場合、前払いをお願いすることもあります。ご了承のほど、お願いします。

データリソース社はどのような会社ですか?

当社は、世界各国の主要調査会社・レポート出版社と提携し、世界各国の市場調査レポートや技術動向レポートなどを日本国内の企業・公官庁及び教育研究機関に提供しております。

世界各国の「市場・技術・法規制などの」実情を調査・収集される時には、データリソース社にご相談ください。

お客様の御要望にあったデータや情報を抽出する為のレポート紹介や調査のアドバイスも致します。

|

|